3 reasons for robotic automation

/ 4 min readRobotic automation is on the rise: according to the World Robotics Report 2023, Germany is one of the most automated countries in the world. The robot density in the manufacturing industry now stands at 415 installed industrial robots per 10,000 employees. A similar trend is emerging on a global level. A new record was set with 151 robots per 10,000 employees. But why do so many companies rely on the support of robots?

The market demands ever faster, cheaper and more specific products - at a time when there is a shortage of skilled workers. In order to meet these challenges, innovations are required – a realm where many have discovered the benefits of robot automation. It is considered particularly attractive as it overcomes several hurdles at once and not only benefits employers.

1. Workforce relief

Experts estimate that the German economy is short of almost 400,000 skilled workers every year. In addition to demographic trends, poor working conditions are one of the main causes of the problem, making it increasingly difficult to recruit suitable workers.

As demographic change can only be solved in the long term, working conditions are proving to be an effective lever. By improving them, the personnel problems can also be solved. Similar to the use of a cordless screwdriver, robots are now simplifying the lives of their human colleagues. They assume tasks that others avoid because of the undesirable working conditions they entail.

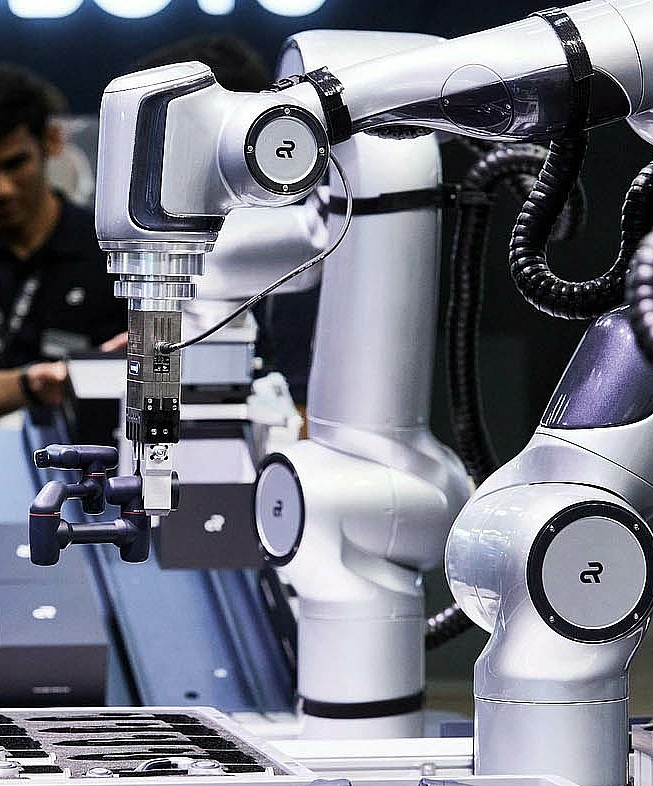

Dispensing is a suitable example of this. Dispensing, i.e. the targeted application of liquids, is not only monotonous, but sometimes also dangerous. This is due to the formation of toxic vapors. With successful automation, a robot takes over dispensing, while the colleague previously responsible for it can pursue more diverse tasks. This relief can also be transferred to other industrial applications. Machine tending, assembly, quality inspection and finishing are also known for their monotonous and stressful working conditions.

Employee satisfaction also benefits from the improved working conditions, as employees can now focus on more valuable and varied tasks. At the same time, the workforce is protected from potential work-related accidents. This also benefits the reputation of the profession, which in turn makes it easier to recruit skilled workers.

2. Improved quality

Longer working hours with better quality? That sounds like a contradiction. People are not machines - and that's a good thing. Unlike our mechanical helpers, we reach our limits at some point. Tiredness sets in. This leads to errors, which in turn affect quality.

Robots hold a distinct edge in this scenario: fatigue doesn't affect them. They work around the clock and do not need any rest periods - while maintaining the same level of quality. Even after a thousand repetitions, there are no deviations.

This is due to the high repeatability of our robots. It describes the deviation with which a certain position can be reached again. Regarding the Yu 5 Industrial from Agile Robots, the repeatability is 0.05 mm. This corresponds approximately to the thickness of a human hair. Therefore, the maximum deviation is marginal, even after countless versions.

These capabilities are crucial for product quality, which requires a high degree of consistency. Through this approach, a high-quality standard is achieved, while avoiding potential errors or flaws.

3. Increased productivity

Increased productivity is the overall positive result achieved by robot automation. With its help, production becomes more efficient while output is maximized. Improved quality leads to a reduction in errors, resulting in fewer rejects, rework and repairs. This shortens the overall production time and has a positive effect on resource utilization. At the same time, improved product quality has a positive impact on customer loyalty. Satisfied customers are more likely to make repeat purchases from a company.

Employee satisfaction also has a decisive influence on productivity. Generally, employees who maintain a balanced workload, with fewer monotonous or physically demanding tasks, tend to be more motivated and committed to their roles.

The continuous, round-the-clock production facilitated by our robots, however, has the most obvious effect on boosting productivity. With the help of our lightweight robots, production cycles are significantly shortened as they work non-stop and achieve higher cycle times. At the same time, they enable the introduction of unmanned night shifts, which increase the overall production volume. Alongside reduced operating costs, frequently achieve self-amortization within mere months of implementation.

Moving with the times

The increasing density of robots proves the triumphant advance of robots right. More and more companies of different sizes are benefiting from the advantages of the mechanical helpers. Robot automation has come to stay. It is also increasingly finding its way into German SMEs. It is an important part of the long-overdue innovation push - and will continue to sustainably improve working conditions, quality and productivity.

Robot automation has come to stay. It is also increasingly finding its way into German SMEs. It is an important part of the long-overdue innovation push - and will continue to sustainably improve working conditions, quality and productivity.

Find out more about our solutions or contact or our experts for a quote.